Welcome to Quality Thermopack & Insulation Industries

Process

Process

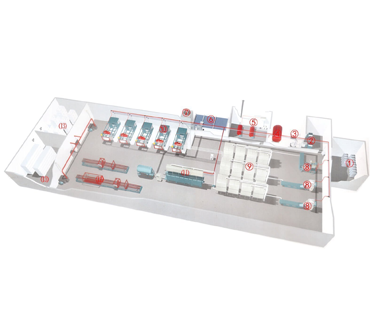

Production Process:

Visual Representation and Step-by-Step Explanation of the EPS Production Process

Slide 1

Slide 2

Slide 3

Slide 4

Slide 5

Slide 6

Slide 7

Slide 8

Slide 9

Slide 10

Slide 11

Slide 12

Slide 13